Description

Winner motorized control ball valve consists of 6N.m/10N.m WAV4-… series rotary actuator and WCBS… series or W8BV...series brass ball valve. Equal percentage flow characteristic guarantees the valve performances of stability. Control ball valves are widely used in HVAC system, heating system, water treatment equipment, and water running control in industrial automation, such as: AHU, flesh air-handling unit, differential pressure control unit and heat exchanger for flow regulation and on/off control.

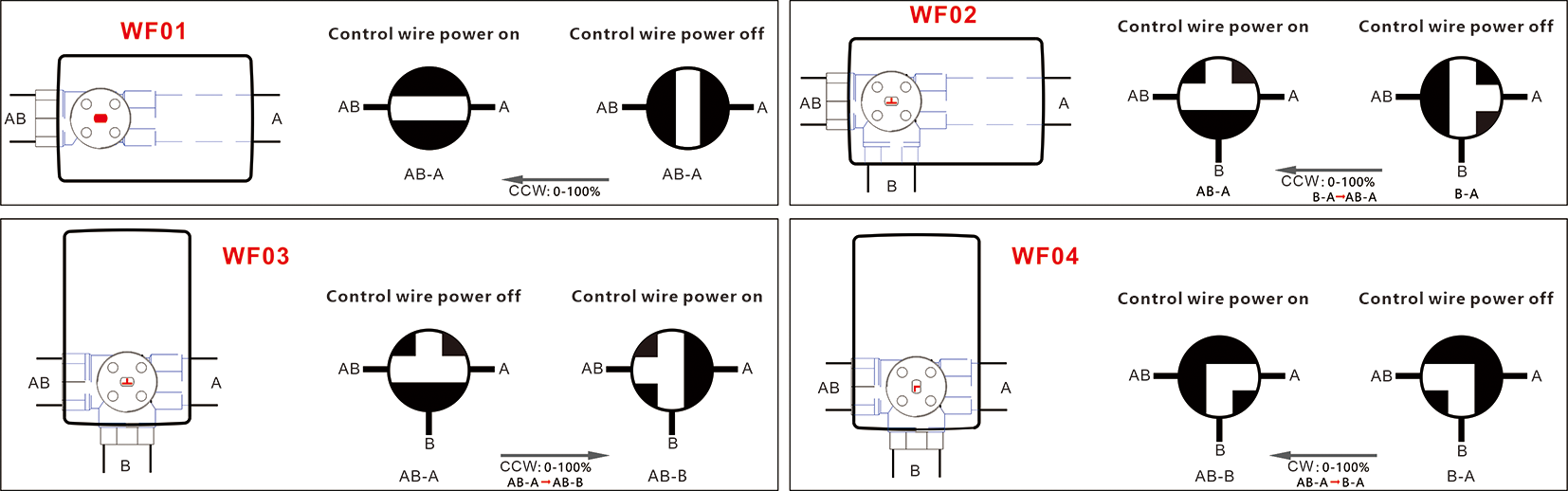

Operational mode

Winner electric control ball valve is motor-operated by a type of WVA4-1…, WAV4-2…, and WAV4-3… actuator. The actuator is controlled by a modulating on/off , 3-point or proportional control system and move the ball of the valve, to the opening position dictated by the control signal.

Technical data

Valve body:

Medium: cold/hot water, with 50% glycol Temperature of medium: 2°C...90°C

Rated pressure: PN20 Pipe connector: internal thread

Ambient temp. range: −5…+60°C;0…90%RH Size: G1/2" -G2"

Valve type: 2-way and 3-way Flow characteristic: equal percentage, on/off

Brass Ball Valve Body Material

WCBS...Series Valve body: forged brass, Hpb59-1 Seal: ball: HNBR+PTFE Ball : SS304 Stem: HNBR O-rings, with 3 O-ring

Model No.

Valve Type DN(mm)

Inch

Kvs(m3 /h)

Pmax(KPa)

Ps(KPa)

WCBS232

2 way DN32

11/4

16

1000

1400

WCBS240

DN40

11/2

25

1400

WCBS250

DN50

2

43

1400

WCBS332

3 way DN32

11/4

16

1400

WCBS340

DN40

11/2

25

1400 WCBS350

DN50

2

43

1400

W8BV...Series thread brass ball valve Valve body: forged brass, Hpb59-1 Seal: ball: EPDM+PTFE Ball: SS304 or Brass chrome plating Stem: FKM O-rings, with 3 O-ring

Model No.

Valve Type DN(mm)

Inch

Kvs(m3 /h)

Pmax(MPa)

Ps(KPa)

W8BV232

2 way DN32

11/4

16

1000

1400

W8BV240

DN40

11/2

25

1400

W8BV250

DN50

2

43

1400

W8BV332

3 way

T-type

DN32

11/4

16

1400

W8BV340

DN40

11/2

25

1400 W8BV350

DN50

2

43

1400

Actuator

WVA4-1… 230 VAC±15%, 3-point

WVA4-2… 24VAC/DC±15%,3-point

WVA4-3… 24VAC/DC±15%, proportional (0-10VDC/0-20mA, 2-10VDC/4-20mA)

WVA4-3...-2 12VDC, proportional (0-10VDC/0-20mA, 2-10VDC/4-20mA)

Output torque: 3 type, 4N.m, 6N.m and 10N.m Angle of rotation: 90°

Manual handle Automatic overload protection system

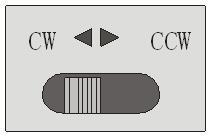

Manual selection of ball rotation direction: C.W. /C.C.W, factory setting is C.W.

Protect rank: IP54 Operation time: 70S-120S

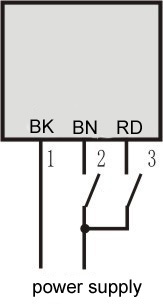

WVA4-1… 230 VAC±15%, 3-point

Brown wire is power on counterclockwise rotation, valve open

Red wire is power on clockwise rotation, valve close

Brown or red wire is power off Valve keep the current position

WVA4-2… 24VAC/DC±15%, 3-point

Brown wire is power on counterclockwise rotation, valve open

Red wire is power on clockwise rotation, valve close

Brown or red wire is power off Valve keep the current position

WVA4-3… 24VAC/DC±15%, proportional (0-10VDC/0-20mA, 2-10VDC/4-20mA)

WVA4-3…-12 12VDC

Black wire and brown wire are the power wire.

Yellow wire accept 0-10V control signal to control the valve’s open angle.

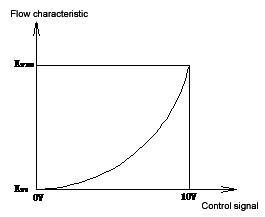

Flow characteristic

Input 0-10VDC control signal

Flow characteristic: equal percentage

Flow range: 0%-100%

Model No.

Working Voltage

Actuator type

Output torque

Consumption

On/off time Valve body

WVA4-106

230VAC

3-point

6N.m

5VA

90-120s DN50,DN40,DN32,

WVA4-110

10N.m 6VA DN50

WVA4-206

24VAC/DC

6N.m

6VA

DN50,DN40,DN32,

WVA4-210

10N.m

DN50

WVA4-306

24VAC/DC

0(2)-10VDC&(0)4-20mA

6N.m

DN50,DN40,DN32,

WVA4-310

10N.m

DN50

WVA4-306-12

24VAC/DC

6N.m

3VA

DN50,DN40,DN32,

WVA4-310-12 10N.m

DN50

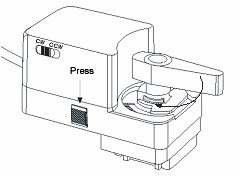

Installation:

1. Ensure that the valve body is in the full open status.

2. Ensure that the actuator is in the fully open position as the follow picture:

3. Aligning the valve stem, press down the aluminum alloy spindle.

Change of running direction

The rotation can be reversed by pushing the CCW/CW switch on the casing.

Factory settings: "CW"

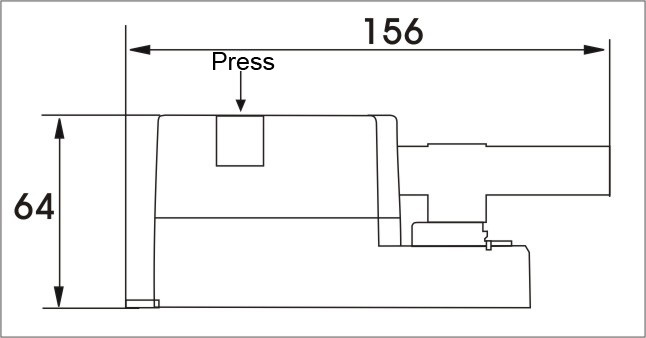

Dimension and Wiring

Actuator

WVA4-106, WVA4-206, WVA4-306 WVA4-110, WVA4-210, WVA4-310 WVA4-106,WVA4-110 WVA4-206,WVA4-210 WVA4-206-2, WVA4-210-2 WVA4-306,WVA4-310 WVA4-306-2, WVA4-310-2

WVA4-3… Flow characteristic

WVA4-3… Flow characteristic